Precision is everything in proton therapy—both inside the treatment room and in the architecture that surrounds it. To that end, shielding design is an essential component of any proton therapy center. It protects patients, staff, and the surrounding community from stray radiation, ensuring that every beam stays exactly where it’s intended to go.

Building that level of safety doesn’t happen by accident. It’s the result of decades of research, modeling, and collaboration between architects, engineers, and physicists—all working to contain a proton beam traveling at two-thirds the speed of light.

In this article, we’ll go behind the scenes—literally—as we discuss the importance of shielding, what it does, and why it matters.

The Physics Behind the Walls

A proton beam is generated in an accelerator and guided through an elaborate network of magnets and vacuum tubes before it reaches the patient. Along the way, it produces neutrons—uncharged particles that can scatter and penetrate materials differently than protons or photons.

While the direct beam is tightly controlled, these secondary neutrons pose a unique challenge. They must be absorbed before they can escape the treatment vault. That’s where shielding comes in.

Each treatment room is essentially a self-contained fortress designed to hold radiation within its walls. Historically, centers might include up to five treatment rooms, though the industry standard has moved closer to two or three. Regardless of configuration, every room must be isolated from the next to prevent cross-room exposure and ensure that no radiation reaches adjacent clinical spaces.

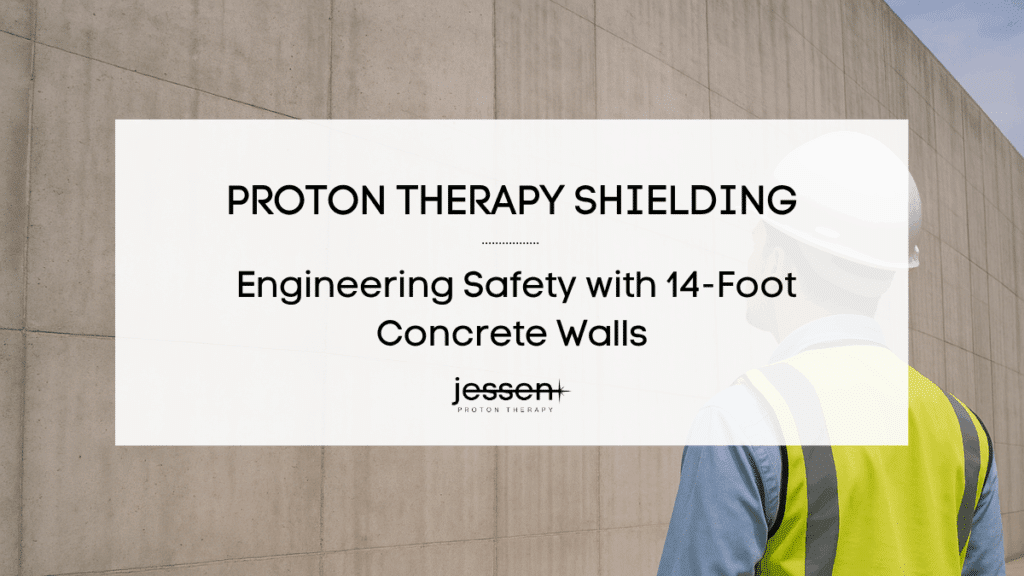

The solution: massive, heavily reinforced walls—often 14 feet thick—that absorb and attenuate radiation before it can move beyond the vault.

Why 14-Foot Concrete Walls Became the Standard

Over time, research and real-world performance have shown that concrete provides the most effective, reliable, and cost-efficient shielding material for proton therapy centers. But not just any concrete will do.

The mix is carefully engineered to balance density, composition, and workability. Too porous, and radiation can pass through. Too dense, and the material can crack during curing. Each pour must be monitored to ensure uniform consistency and structural integrity.

At Jessen Proton, we’ve explored—and re-explored—countless ways to optimize that process. Decades of experience have fine-tuned how and where shielding is placed, minimizing overbuilding without compromising safety. In most modern facilities, walls are 14 feet thick, roofs are of similar depth, and even the floors are strategically layered to prevent leaks or seepage into groundwater.

This depth is the result of iterative modeling and real-world data confirming that it’s what’s required to keep radiation levels well below federal exposure limits.

Collaborating with Shielding Consultants and Physicists

Shielding design begins long before concrete is poured. During planning, the project architect partners closely with a certified medical physicist or shielding consultant who specializes in proton therapy centers.

This collaboration determines exactly how much shielding is needed—and where. The consultant models beam trajectories, evaluates neutron scatter patterns, and identifies potential “hot spots” within and around the vault. The architect then incorporates those findings into the overall facility layout.

That relationship is critical. A few inches of miscalculation in shielding thickness or placement could have enormous implications later. Working as a team from the start ensures that every line drawn and every cubic yard of concrete poured serves a very specific purpose.

Exploring Alternative Materials

Concrete has remained the industry standard, but that hasn’t stopped the field from testing other materials that might save time or cost.

At one point, researchers at Hampton University even partnered with the U.S. Navy to study shielding materials used in submarines—engineered to protect crews from onboard radiation. While promising in theory, the results confirmed that using those advanced composites would be significantly more expensive than poured concrete.

Precast concrete panels have also been explored. They could, in theory, speed up construction by allowing sections of walls to be manufactured off-site and assembled on-site like giant puzzle pieces. But when it comes to cost and performance, poured-in-place concrete continues to win. Each proton center’s configuration and beam line geometry are unique, making it difficult to standardize precast modules without expensive customization.

In other words, what looks like an opportunity to save time on paper often creates more complexity in practice.

Designing for Safety from the Ground Up

Shielding doesn’t stop at the walls.

The roof structure of a proton therapy vault typically mirrors the wall thickness—up to 14 feet of concrete reinforced with rebar and internal supports. These roofs also include massive hatches that allow the delivery of treatment equipment. Once that equipment is installed, the hatches are sealed and the vault becomes a self-contained unit.

The floors, meanwhile, serve a dual role. They must prevent water infiltration and protect against environmental exposure without unnecessarily overbuilding. Because the primary concern is upward radiation (not groundwater radiation), floor thickness can be reduced compared to walls and ceilings. Specialized drainage and waterproofing systems are integrated early in the design process to prevent seepage and maintain the vault’s structural integrity over decades of use.

Addressing Community Concerns

Understandably, communities often have questions about radiation safety when a proton therapy center is being planned nearby. Shielding is the answer to most of those concerns.

The combination of 14-foot-thick concrete walls, ceilings, and floors—backed by rigorous modeling and testing—ensures that radiation exposure outside the treatment area is far below permissible limits.

In fact, radiation levels measured just outside a completed vault are often indistinguishable from normal background radiation. The layers of shielding, combined with operational safety protocols, make proton therapy one of the safest radiation treatment environments in healthcare.

Proven Solutions Across Institutions

Every proton therapy center Jessen Proton has supported shows how shielding design adapts to the needs of each institution while maintaining universal safety standards.

- Hampton University worked closely with physicists and the U.S. Navy to explore advanced materials, ultimately confirming that poured concrete remains the gold standard.

- Northern Illinois University implemented optimized wall configurations to streamline construction while maintaining shielding integrity.

- OSF St. Francis Medical Center and Kettering Hospital integrated shielding early in their architectural design, allowing for efficient sequencing of vault construction and reducing rework during later phases.

Across these and other projects, one constant remains: shielding is both a science and an art. It requires the precision of a physicist and the practicality of an architect to create a space that is safe, functional, and enduring.

Building More Than Walls

Proton therapy shielding is about precision, accountability, and care. Every cubic yard of concrete poured represents a promise: that the patients, staff, and surrounding community will remain protected for decades to come.

At Jessen Proton, that promise guides every project we design. Shielding may not be the most visible part of a proton therapy center, but it’s the one that makes everything else possible.